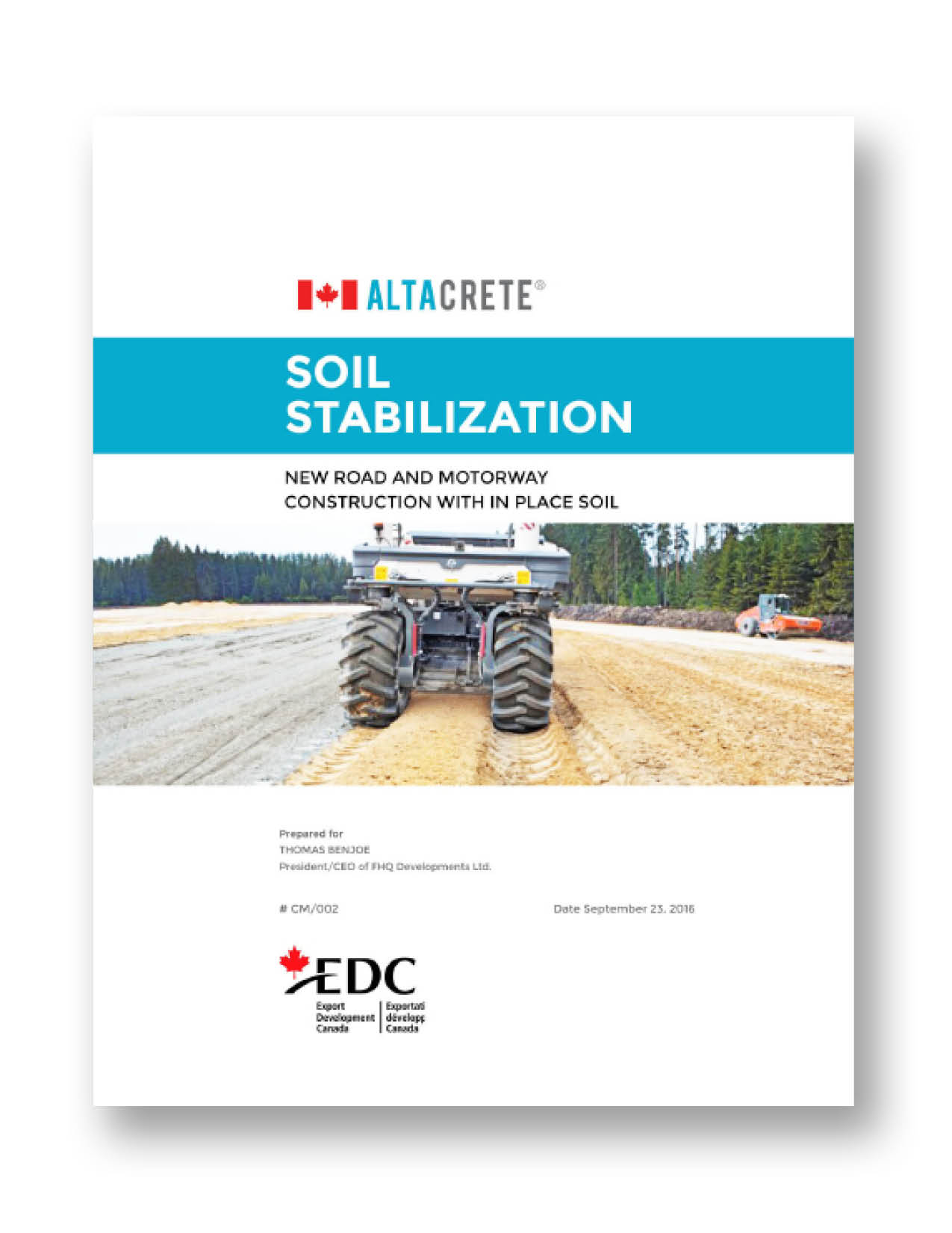

Anyone who has bumped his way over a pothole-filled section of roadway can tell you that the lack of a good foundation makes a big difference in pavement performance. A well-designed and well-constructed pavement base is necessary to provide the thickness and strength required to carry heavy traffic loads, minimize failures, and create smoother rides.

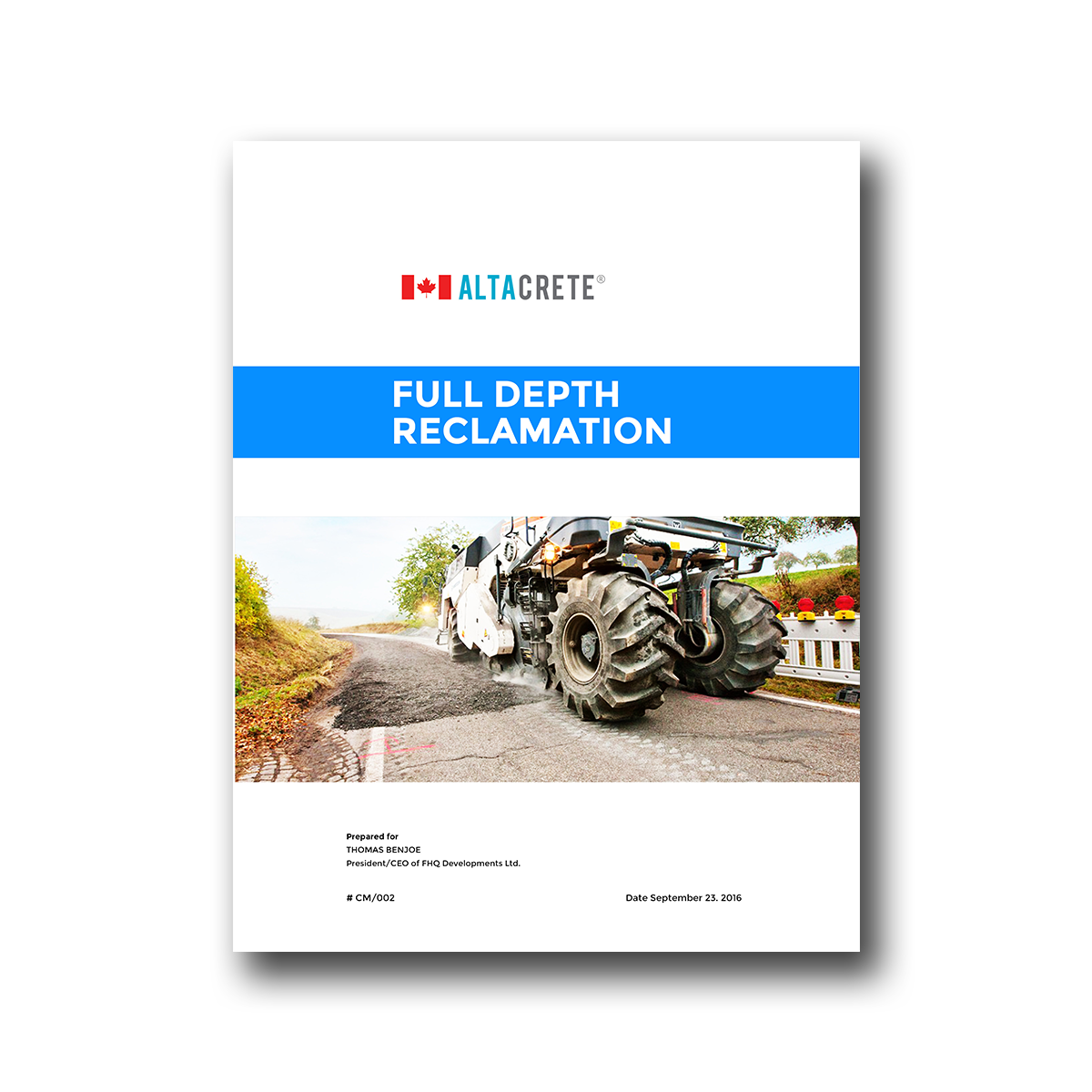

Stabilized pavement bases, such as soil-cement and cement-treated bases, have provided economical, long-lasting pavement foundations for nearly 70 years. Many engineers and public works officials are turning to a process called full-depth reclamation (FDR) with cement for a quality stabilized pavement base. FDR recycles the materials from deteriorated asphalt pavements, and, with the addition of cement, creates a new stabilized base. A surface consisting of a thin bituminous surface treatment, hot-mix asphalt, or concrete completes the rebuilt road. The recycled base will be stronger, more uniform, and more moisture resistant than the original base, resulting in a long, low-maintenance life. And most important, recycling costs are normally at least 25% to 50% less than the removal and replacement of the old pavement.

What roads are candidates for FDR with cement?FDR is most appropriate under the following conditions:

- The pavement is seriously damaged and cannot be rehabilitated with simple resurfacing.

- The existing pavement distress indicates that the problem likely exists in the base or subgrade.

- The existing pavement requires patching.

- The pavement structure is inadequate for the current or future traffic.

Serious damage or base failure

The engineer can evaluate the reasons for pavement failure by observing the types of distress that are visible. For example, alligator cracking, deep depressions, or soil stains on the surface are all signs of base or subgrade problems in the pavement structure.

Excessive patching

Although patching is often necessary to keep a road serviceable, it can be expensive. In fact, once the area of full-depth patching exceeds 15% to 20%, simple economics makes it less expensive to use FDR rather than to perform the patching. Of course the final product achieved with FDR is far superior to a road that is heavily patched.

MATERIAL CONSERVATIONDeteriorating roads are a constant problem for cities and counties. FDR with cement can rebuild worn-out asphalt pavements by recycling the existing roadway. The old asphalt and base materials are pulverized, mixed with cement and water, and compacted to produce a strong, durable base for either an asphalt or concrete surface. FDR uses the old asphalt and base material for the new roadway base. There’s no need to haul in aggregate or haul out old material for disposal. Truck traffic is greatly reduced, and there is little or no waste.

FDR with cement also conserves virgin construction materials and makes smart economic and strategic sense. A century of modern growth and urbanization in America has depleted once-plentiful aggregate supplies. Frequently, aggregates either come from distant quarries at great expense or from local sources offering only marginal quality.

Continuing to exhaust these valuable resources to rebuild existing roads only propagates and accelerates the problem. Additionally, if old asphalt and base materials are not recycled, they must be disposed of or stockpiled, increasing transportation costs and using valuable landfill space. In some locales, old asphalt can no longer be landfilled. Environmental laws are becoming stricter, thus adding to the expense of mining new materials and landfilling old.

FDR with cement makes the reconstruction of old roads a largely self-sustaining process. The original “investment” in virgin road materials becomes a one-time cost, which is reclaimed through cement stabilization and addition of a new, thin surface course.

Stabilizing the old asphalt creates a strong foundation for the pavement. Usually there is little need for material to be removed or added. The old, brittle asphalt, when pulverized, becomes “black gravel” that will readily bond to hydrated cement. In cases where the existing asphalt pavement does not meet the aggregate requirements for a good stabilized base, additional aggregates can be easily incorporated into the recycled aggregate during construction.

DESIGN AND CONSTRUCTION

The basic procedure of FDR with cement is simple and traffic can be maintained during construction. The complete recycling process can be finished in one day allowing local traffic to return almost immediately. The procedure includes the following steps:

Site investigation: The site should be investigated to determine the cause of failure. Core samples or test holes should be used to determine layer thicknesses and to obtain samples of the materials to be recycled, which can include asphalt surface, base course aggregate, and subgrade.

Thickness design: Pavement thickness can be determined by using the American Association of State Highway and Transportation Officials Guide for Design of Pavement Structures. Alternatively, the Portland Cement Association (PCA) handbook, Thickness Design for Soil-Cement Pavements, can be used.

Lab evaluation: Material samples from the site should be pulverized in the lab to create an aggregate-soil mix that will be similar to that expected from the reclamation process. The mix design includes the determination of maximum dry density and optimum moisture content. If unconfined compressive strength is used to determine cement content, a seven-day strength of 300 to 400 psi is recommended. PCA’s Soil-Cement Laboratory Handbook, can be used to determine the mix design.

Pulverization: Construction begins with pulverizing the existing asphalt pavement using equipment that resembles a large rototiller. This pulverizing/mixing equipment also is commonly used to mix cement with soils when stabilizing pavement subgrades. The depth of pulverization is usually 6 to 10 inches, which on secondary roads will typically include all of the surface and base, plus some part of the subgrade. To achieve the proper gradation after pulverization, more than one pass of the equipment may be necessary. The particle distribution should be such that 100% passes the 3-inch sieve, 95% passes the 2-inch sieve, and at least 55% passes a No. 4 sieve.

Shaping and grading: The pulverized material is shaped to the desired cross section and grade. This could involve additional earthwork in order to widen the roadway. Final base-elevation requirements may necessitate a small amount of material removal or addition.

Spreading cement: Cement is spread in a measured amount on the surface of the shaped roadway, in either dry or slurry form.

Water application: Water is added to bring the aggregate-soil mixture to optimum moisture content (water content is maximum dry density as determined by ASTM D 558).

Mixing: The aggregate-soil-cement-water mixture is combined and blended with the pulverizing/mixing machinery. More than one pass of the mixer may be required to achieve a uniform blend of materials.

Compaction: The mixture is compacted to the required density of at least 96% of standard Proctor density (ASTM D 558). The compaction is usually performed with smooth-wheeled vibratory rollers. A pneumatic-tired roller may follow to finish the surface. Final compaction should take place no more than three hours after initial mixing of the cement. The field density and moisture are monitored for quality-control purposes.

Curing: The goal of curing is to keep the base continuously moist so the cement can hydrate. The completed base should be coated with bituminous primer to seal in the moisture. Another method of curing is to keep the base constantly moist by spraying water on the surface.

Pavement surface: The new pavement surface consisting of a bituminous surface treatment, hot-mix asphalt, or concrete is constructed to complete the FDR process.

Quality control: FDR with cement follows the same basic procedures used for normal soil-cement operations. The success of a reclamation project depends upon the careful attention to the following control factors:

- Adequate pulverization

- Proper cement content

- Proper moisture content

- Adequate density

- Adequate curing.

FDR can be an effective solution for cities working to find an economical roadway design that ensures performance for the life of the pavement.

Advantages of stabilization

- Cement stabilization increases the stiffness and strength of the base material. A stiffer base reduces deflections due to the traffic loads, which results in lower strains in the asphalt surface. This delays the onset of surface distress, such as fatigue cracking, and extends pavement life.

- The strong, uniform support provided by cement stabilization results in reduced stresses applied to the subgrade. A thinner cement-stabilized section can reduce subgrade stresses more than a thicker layer of untreated aggregate base. Subgrade failures, potholes, and road roughness are thus reduced.

- Moisture intrusion destroys pavement bases. Cement-stabilized pavements form a moisture-resistant base that keeps water out and maintains higher levels of strength, even when saturated.

- A cement-stabilized base also reduces the potential for pumping of subgrade fines.